Engine Rebuild

The bus came with a 1300 cc engine, which we found underneath lots of collected parts in the cargo bay. The original 1500 cc engine must have been sold many years ago, so I decided to start looking for another suitable engine, rather than to waste my time trying to get this one back up and running. It would have had a lack of power to move the kombi around at a reasonable pace anyway...

Luckily the panels from the 1300 cc engine were, although rusted, still in a pretty good condition; sandblasting and powder coating made them look brand new! Not much later I stumbled across a 1500 cc H-type engine block, which I had rebuilt by BBT in Belgium whom also recommended to install 1600 cc cylinders.

Putting all the bits and pieces together of the engine is not as complicated as it might seem, as long as you take the time to study a workshop manual and ensure you have all the correct parts available. Maybe needless to say, but make sure you use new gaskets to ensure your new engine wont't be leaking any oil. Gasket kits are cheap and are guaranteed to save you from the nuisance of oil leaks once your project is finished.

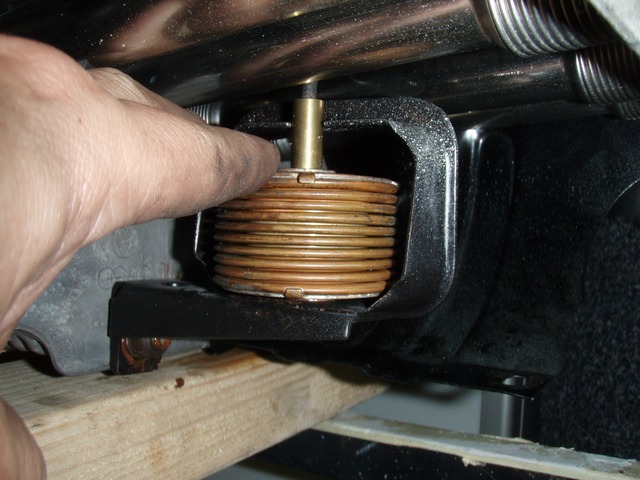

It is not a problem to reuse an engine oil cooler, provided that you did not take it of a jammed engine (replace when in doubt!). Verify that the oil cooler is not leaky by putting it upside-down in a bucket filled with water. Next, plug the outlet of the oil cooler and use a compressor to blow air into the inlet. If you see bubbles coming from the water, you will definitley need another oil cooler...

There is not much you can do with the alternator besides replacing the carbon-brushes, check the windings, contacts and alternator bearings. You can polish the alternator housing to make it look nice and shiny.

Although I usually prefer to keep things original, I got a bit carried away when I was working on the engine: I found some chrome gadgets that gave my engine just that little personal touch. This is of course completely up to your own liking and does nothing to the engine's performance.

The carburettor was completely disassembled and thoroughly cleaned, use compressed air to blow out all parts and fuel channels. Use a carburettor rebuild kit for assembly, which will have all the gaskets, diaphragms and adjusting screws required. Refer to your workshop manual for initial settings of the carburettor.

After the installation of new heat exchangers, exhaust, panels, hoses, inlet manifold and the carburettor, the engine was ready for installation once our Splitty returns from the painter. Finally, top up the engine with 20W50 mineral oil to prevent moisture from corroding any of the inside of your engine whilst it is stored.

Two final remarks with regard to the clutch assembly and the installation of the clutch-plate:

- A diaphragm type clutch assembly allows smoother changing of gears than a conventional three-leaver type assembly.

- I used a piece of pipe with the same diameter as the hole in the middle of the engine’s flywheel to centre the clutch-plate during installation of the clutch assembly. Doing this will ensure the transmission's drive shaft will slide in easily when installing the engine. Alternatively you can buy an adaptor, but this worked great too!

EDIT: 2 years and 25,000 km in since completion of restoration we have had repeated issues with the 3rd cylinder overheating when covering long distances in one go (1000+ km) and eventually blowing up the engine. The main contributing factors to our problems were:

- No thermostat and control flaps installed (as we were initially told they cause more problems than they do any good)

- Small oil cooler used on 1500 cc and smaller engines partly blocks the air flow to the 3rd cylinder, which causes insufficient cooling for 1600 cc cylinders

We went back to the drawing board with our friends from Paruzzi to come up with a reliable solution and ended up building a new single port 1600 cc block with the larger type off-set oil cooler, this also required switching to the wider type dog house. Thermostat and control flaps were installed as per original design and the crankshaft pulley was slightly increased in diameter (desert pulley) to provide more cooling. The carburettor was swapped from a Solex 28 PICT to a 31 PICT 3 to better cater for the 1600 cylinders. This has so far given us a very reliable engine as we are now at 85,000 km and still going strong!